INSTALLATIONS YEAR ROUND

POLYASPARTIC FLOORING

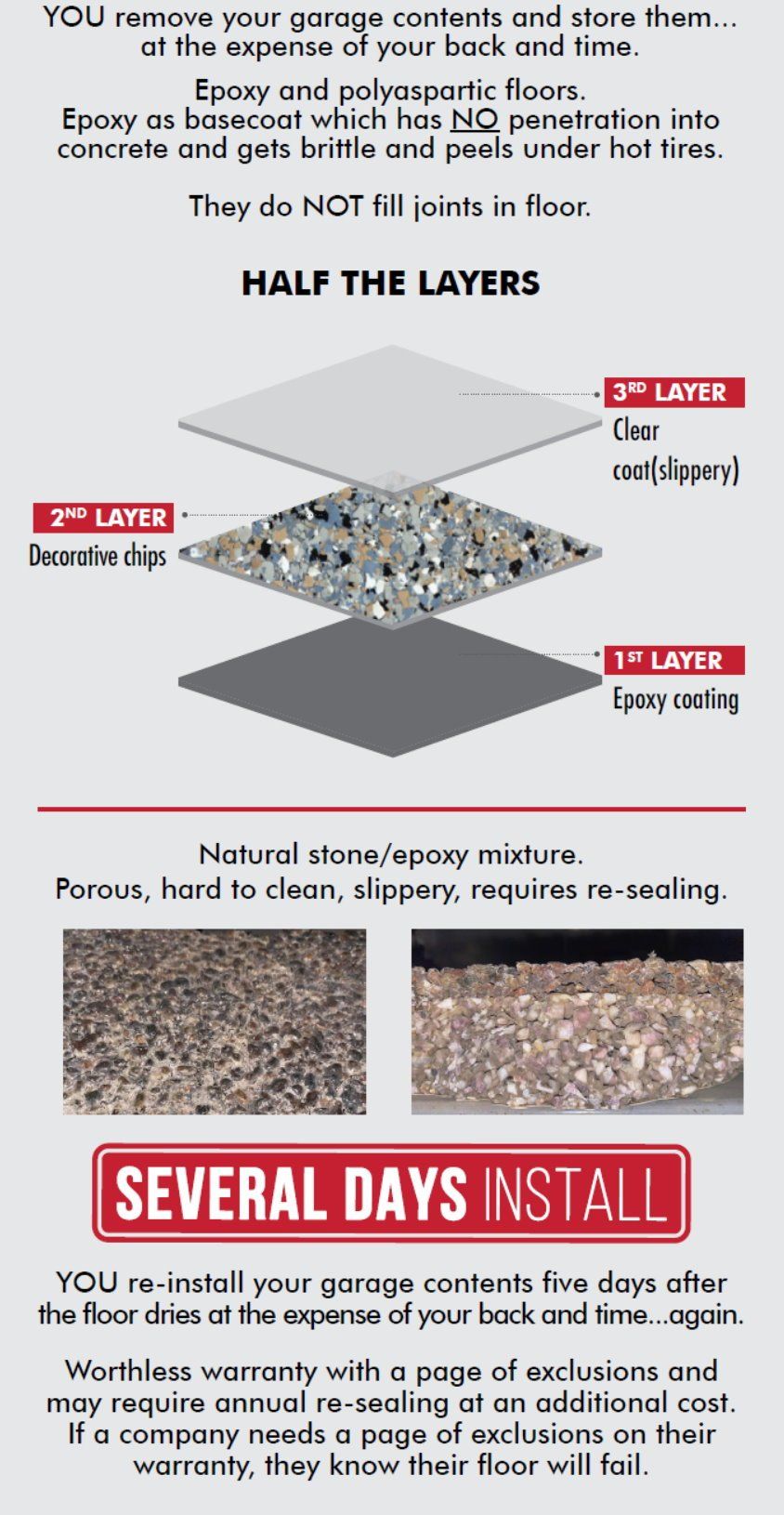

THE OTHER GUYS

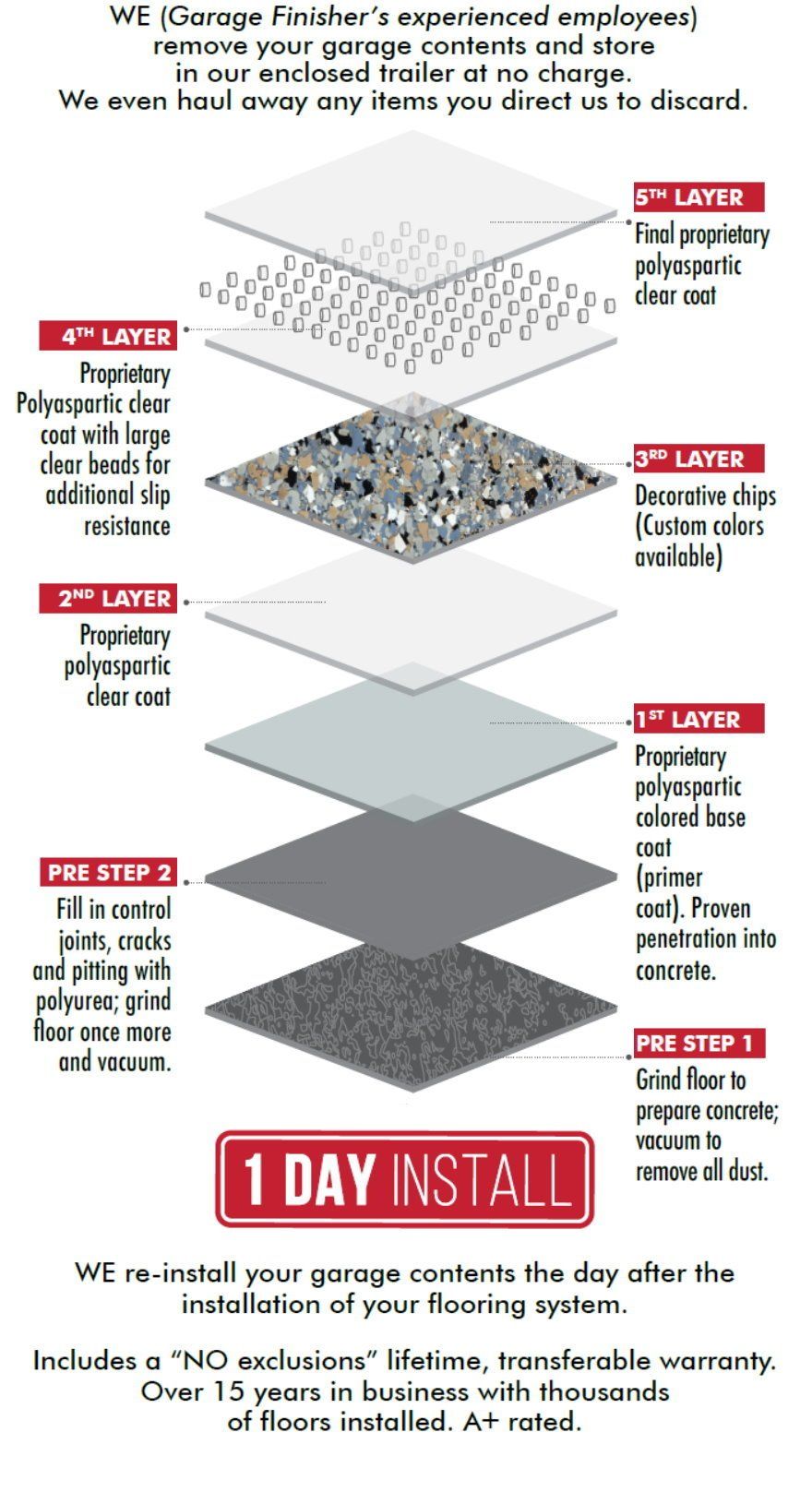

GARAGE FINISHER

THE FOREVER FLOOR

You re-install your garage contents five days after the floors dries at the expense of your back and time...again.

Worthless warranty with a page of exclusions and may require annual re-sealing at an additional cost. If a company needs a page of exclusions on their warranty, they know their floor will fail.

WE re-install your garage contents the day after the installation of your flooring system.

Includes a "NO Exclusions" lifetime, transferable warranty.

Over 15 years in business with thousands of floors installed. A+ rated.

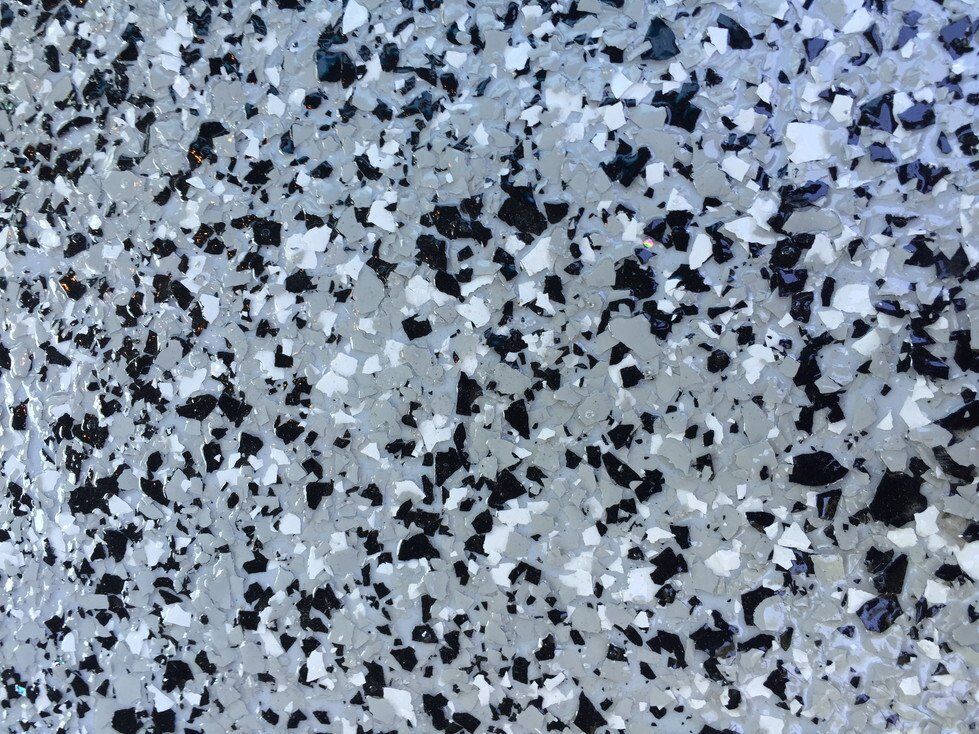

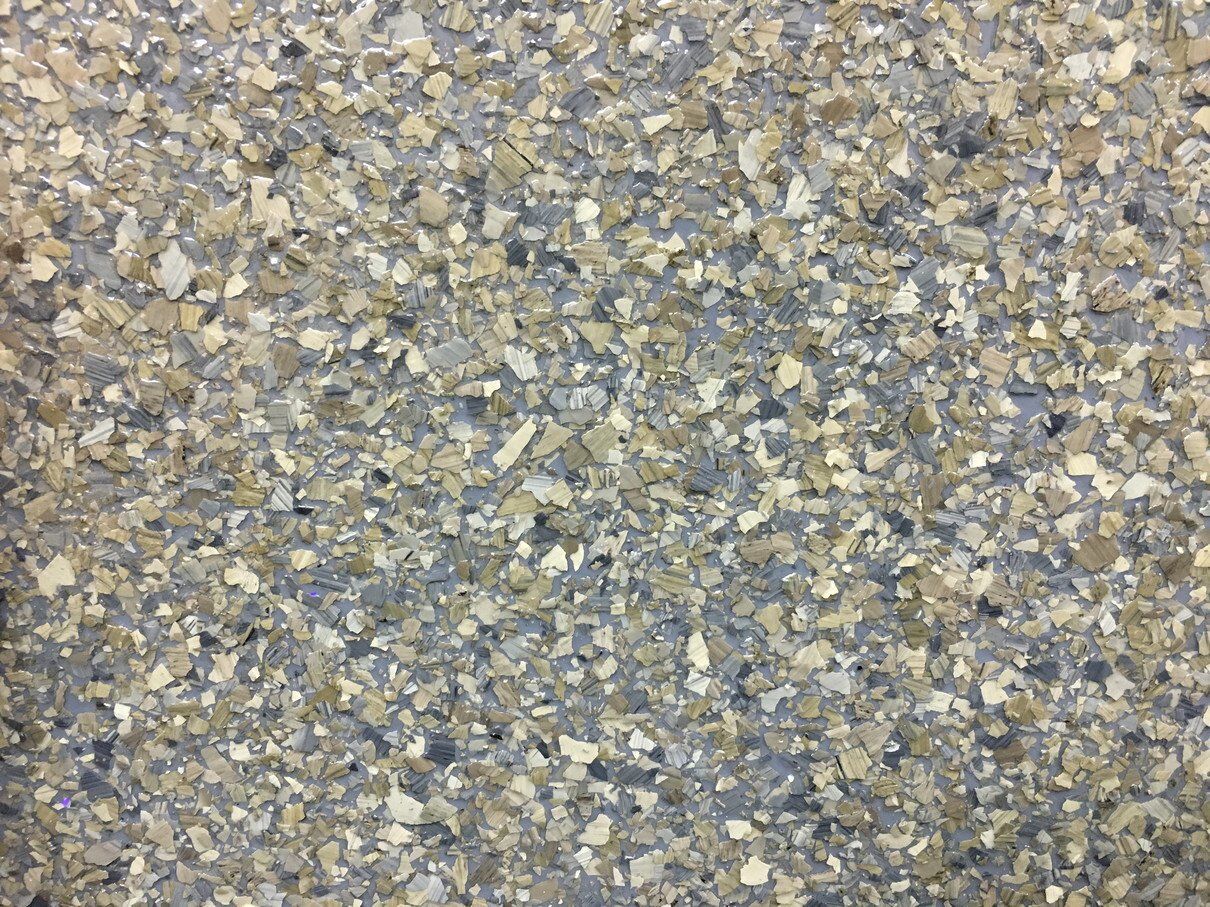

The Forever Floor Color Choices

Click on Color Sample to Enlarge

BEFORE & AFTER

Choose Polyaspartic Floor Coatings for The Best Flooring Surface

When choosing flooring for a garage, basement, warehouse, or other commercial facility, the best option is to resurface concrete with a resinous coating. Which type of flooring is best? More and more homeowners and businesses are discovering the advantages of polyaspartic floor coatings as they have proven to be the superior choice.

Garage Finisher takes polyaspartic flooring to a higher level. Our proprietary Forever Floor process takes polyaspartic floor coating and improves on the entire installation process, creating the strongest and most durable flooring you can have installed!

The Advantages of Polyaspartic Coatings

Polyaspartic flooring is a relatively new product. It was first developed in the 1980s and began booming in popularity during the 2000s. More and more businesses and homeowners have discovered that it has numerous benefits over other resinous materials, especially epoxy. Epoxy has been the go-to concrete coating for years, but that’s rapidly changing due to the high failure rate of epoxy.

Polyaspartic flooring is:

More damage-resistant

There's no substance you could put on your garage floor which is more durable than a polyaspartic coating. Epoxy tends to be brittle. It can stand up to some damage but is easily cracked by falling objects and loses its bond to the concrete over time. Polyaspartic floors are resistant to both crushing and falling damage, as well as being able to stand up to use by even large machines such as forklifts and car’s hot tires. Epoxy base coats even if covered with a Polyaspartic topcoat tend to lose adhesion to the concrete and peel/chip, shortening the usable life of the flooring. You will notice many companies that use epoxy have a long list of exclusions to their warranty, even excluding moisture which is ridiculous because of course there is moisture in a concrete.

Better bonding

Most resinous coatings like epoxy simply sit on top of a concrete surface, which makes it easier for them to peel up from the floor. Garage Finisher’s Proprietary Polyaspartic Formulation actually penetrates into the concrete itself, forming a PERMANENT bond with the concrete which is virtually unbreakable.

UV-resistant

Another major drawback of epoxy flooring is that it cannot be exposed to direct sunlight or other ultraviolet light sources. UV light will first cause the epoxy to fade and yellow, then to become even more brittle and peel. Polyaspartic coatings don't have this issue. Polyaspartic floors can be used indoors and outdoors, with no concern for sunlight causing damage or making it brittle.

Chemical-resistant

Polyaspartic flooring can stand up against virtually any chemical that might be spilled on it, including acids or oils which could damage other types of resinous flooring. This protects your floor from staining, as well as ensuring that no hazardous chemicals seep into the soil or groundwater.

Temperature-resistant

Most other resinous coatings require relatively high heat to cure, typically temperatures above 50F. Below that, and the flooring won't set properly. Also, other types of resins tend to fail if exposed to cold for long periods. None of these problems apply to polyaspartic coatings, which can set in almost any temperature and can stand up against extremes of hot or cold better than the alternatives. This also allows Garage Finisher to install year round.

Fast-Curing

Do you need a new floor today? Polyaspartic flooring can make it happen. Other resins typically require multiple days, even 3-5 days or longer, to fully cure and become usable. Polyaspartic coatings are fully dry within just a few hours. A floor installed today can be used tomorrow.

Beautiful

Polyaspartic coatings can come in any color you want, and our Forever Floor process includes a dedicated layer that features decorative chips to create a floor that works hard while still looking good year-round.

Garage Finisher Forever Floor Makes Polyaspartic Flooring Even Better!

We aren't content simply using polyaspartic floor coatings. We wanted to create the best commercial and residential flooring system on the market, combining polyaspartic products with our own extensive knowledge of concrete coatings. The result is our Proprietary Forever Floor System.

Here's how it works:

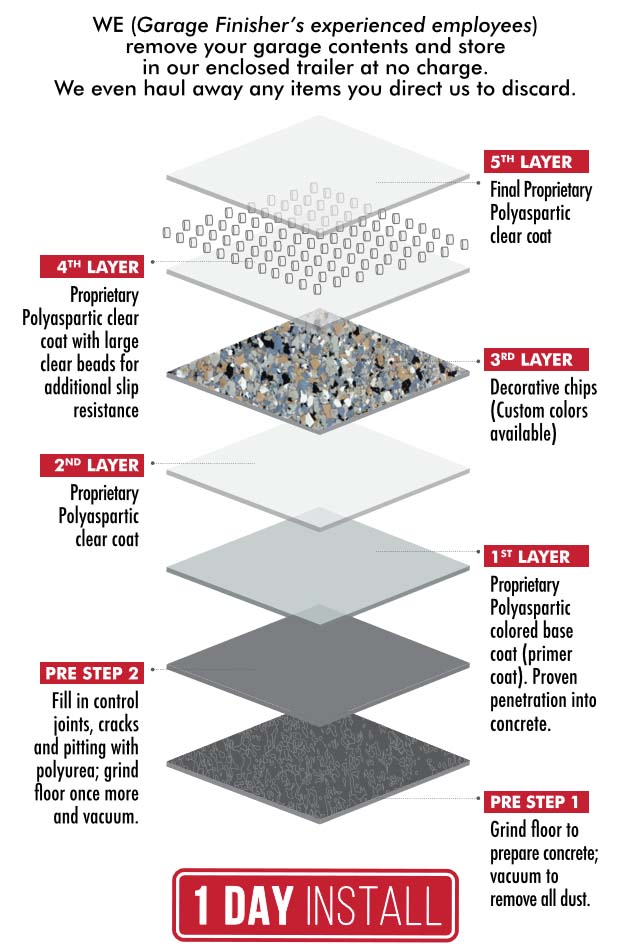

Concrete preparation

We use a custom two-step process to prepare the concrete for its coating. First we grind the floor down to create the proper texture and rid the concrete of contaminants. Then, we go further: Any visible pits, cracks, or other flaws in the floor are filled in with a fast-curing polyurea mixture. Then we grind the surface again and thoroughly clean it, resulting in the best possible base for a floor coating.

After that, we utilize five layers to create the most durable and attractive floor on the market.

Layer one

The first layer is a primer coat of our proprietary polyaspartic formulation, designed to penetrate deep into the concrete and create an unbreakable bond with the surface. This underlayer is also colored to create a slightly dimensional look to the flooring and add to its aesthetics.

Layer two

The second layer is a clear coating of our polyaspartic material, which binds to the first layer and adds strength to the flooring. Garage Finisher uses this separate layer from the base layer to make sure the decorative chips properly bond without detracting from the adhesion of the colored base layer. Chips that are directly broadcasted into an epoxy or polyaspartic base layer cause the base layer to lose adhesion to the concrete over time.

Layer three

The third layer is decorative and adds impact resistance. This layer has a large variety of options including custom colors. Concrete flooring doesn't need to be boring and can really wow your visitors!

Layer four

The fourth layer of polyaspartic material incorporates special clear beads, which add grip to the flooring. One of the few drawbacks of polyaspartic and epoxy floors is that they can be a slippery, so we make sure this isn't a problem. Our floors are safe to walk on, even when wet.

Layer five

Finally, another clear coat is applied on top to lock in the special clear slip beads and add one more extra level of strength. This is how our Forever Floor can stand up to so much abuse and why we can offer an unconditional lifetime warranty.

And all this can be done in a single day due to our fast-drying formula and extremely experienced crew.

Finish Your Flooring Right with Garage Finisher

Whether you're coating a garage floor or any other commercial surface, Garage Finisher offers the strongest and most durable flooring in Ohio - and our customers agree! Our extensive experience and custom installation methods ensure that your Forever Floor truly lives up to its name.

Choose Polyaspartic Floor Coatings for The Best Flooring Surface

When choosing flooring for a garage, basement, warehouse, or other commercial facility, the best option is to resurface concrete with a resinous coating. Which type of flooring is best? More and more homeowners and businesses are discovering the advantages of polyaspartic floor coatings as they have proven to be the superior choice.

Garage Finisher takes polyaspartic floor coating to a higher level. Our proprietary Forever Floor process takes polyaspartic floor coating and improves on the entire installation process, creating the strongest and most durable flooring you can have installed!

The Advantages of Polyaspartic Coatings

Polyaspartic flooring is a relatively new product. It was first developed in the 1980s and began booming in popularity during the 2000s. More and more businesses and homeowners have discovered that it has numerous benefits over other resinous materials, especially epoxy. Epoxy has been the go-to concrete coating for years, but that’s rapidly changing due to the high failure rate of epoxy.

Polyaspartic flooring is:

More damage-resistant

There's no substance you could put on your garage floor which is more durable than a polyaspartic coating. Epoxy tends to be brittle. It can stand up to some damage but is easily cracked by falling objects and loses its bond to the concrete over time. Polyaspartic floors are resistant to both crushing and falling damage, as well as being able to stand up to use by even large machines such as forklifts and car’s hot tires. Epoxy base coats even if covered with a Polyaspartic topcoat tend to lose adhesion to the concrete and peel/chip, shortening the usable life of the flooring. You will notice many companies that use epoxy have a long list of exclusions to their warranty, even excluding moisture which is ridiculous because of course there is moisture in a concrete.

Better bonding

Most resinous coatings like epoxy simply sit on top of a concrete surface, which makes it easier for them to peel up from the floor. Garage Finisher’s Proprietary Polyaspartic Formulation actually penetrates into the concrete itself, forming a PERMANENT bond with the concrete which is virtually unbreakable.

UV-resistant

Another major drawback of epoxy flooring is that it cannot be exposed to direct sunlight or other ultraviolet light sources. UV light will first cause the epoxy to fade and yellow, then to become even more brittle and peel. Polyaspartic coatings don't have this issue. Polyaspartic floors can be used indoors and outdoors, with no concern for sunlight causing damage or making it brittle.

Chemical-resistant

Polyaspartic flooring can stand up against virtually any chemical that might be spilled on it, including acids or oils which could damage other types of resinous flooring. This protects your floor from staining, as well as ensuring that no hazardous chemicals seep into the soil or groundwater.

Temperature-resistant

Most other resinous coatings require relatively high heat to cure, typically temperatures above 50F. Below that, and the flooring won't set properly. Also, other types of resins tend to fail if exposed to cold for long periods. None of these problems apply to polyaspartic coatings, which can set in almost any temperature and can stand up against extremes of hot or cold better than the alternatives. This also allows Garage Finisher to install year round.

Fast-Curing

Do you need a new floor today? Polyaspartic flooring can make it happen. Other resins typically require multiple days, even 3-5 days or longer, to fully cure and become usable. Polyaspartic coatings are fully dry within just a few hours. A floor installed today can be used tomorrow.

Beautiful

Polyaspartic coatings can come in any color you want, and our Forever Floor process includes a dedicated layer that features decorative chips to create a floor that works hard while still looking good year-round.

Garage Finisher Forever Floor Makes Polyaspartic Coatings Even Better!

We aren't content simply using polyaspartic floor coatings. We wanted to create the best commercial and residential flooring system on the market, combining polyaspartic products with our own extensive knowledge of concrete coatings.

The result is our Proprietary Forever Floor System.

Here's how it works:

Concrete preparation

We use a custom two-step process to prepare the concrete for its coating. First we grind the floor down to create the proper texture and rid the concrete of contaminants. Then, we go further: Any visible pits, cracks, or other flaws in the floor are filled in with a fast-curing polyurea mixture. Then we grind the surface again and thoroughly clean it, resulting in the best possible base for a floor coating.

After that, we utilize five layers to create the most durable and attractive floor on the market.

Layer one

The first layer is a primer coat of our proprietary polyaspartic formulation, designed to penetrate deep into the concrete and create an unbreakable bond with the surface. This underlayer is also colored to create a slightly dimensional look to the flooring and add to its aesthetics.

Layer two

The second layer is a clear coating of our polyaspartic material, which binds to the first layer and adds strength to the flooring. Garage Finisher uses this separate layer from the base layer to make sure the decorative chips properly bond without detracting from the adhesion of the colored base layer. Chips that are directly broadcasted into an epoxy or polyaspartic base layer cause the base layer to lose adhesion to the concrete over time.

Layer three

The third layer is decorative and adds impact resistance. This layer has a large variety of options including custom colors. Concrete flooring doesn't need to be boring and can really wow your visitors!

Layer four

The fourth layer of polyaspartic material incorporates special clear beads, which add grip to the flooring. One of the few drawbacks of polyaspartic and epoxy floors is that they can be a slippery, so we make sure this isn't a problem. Our floors are safe to walk on, even when wet.

Layer five

Finally, another clear coat is applied on top to lock in the special clear slip beads and add one more extra level of strength. This is how our Forever Floor can stand up to so much abuse and why we can offer an unconditional lifetime warranty.

And all this can be done in a single day due to our fast-drying formula and extremely experienced crew.

Finish Your Flooring Right with Garage Finisher

Whether you're coating a garage floor or any other commercial surface, Garage Finisher offers the strongest and most durable flooring in Ohio - and our customers agree! Our extensive experience and custom installation methods ensure that your Forever Floor truly lives up to its name.